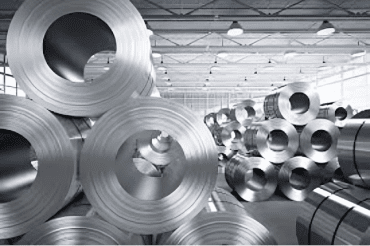

INTECH Bearing Solution (IBS) has focused solely on bearings since 1983. With Mumbai's extensive inventory of over 2000 items, we offer prompt delivery and expert technical guidance for various applications, from precision machine tools to national defense, ensuring reliable supply for critical industries.

Unmatched Quality, Genuine Supply Where Precision Meets Reliability, Powering Your Success with Every Turn of the Bearing

Unlocking Efficiency at the Best Price Quality Bearings for Every Application. Your Success, Our Commitment

Instant Solutions Await! Explore Our Extensive Ready Stock Bearings Selection – Drive Your Success with Swift Efficiency

Rely on Our Bearings for Unrivaled Durability and Performance. Trusted Globally to Keep Your Operations Running Smoothly, Every Time

Elevating Customer Satisfaction Through Exceptional Bearings: Quality, Reliability, and Performance That Exceed Expectations

Our Commitment to Excellence Extends with Comprehensive After-Sales Bearing Service, Ensuring Your Continued Success

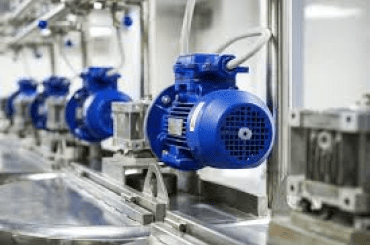

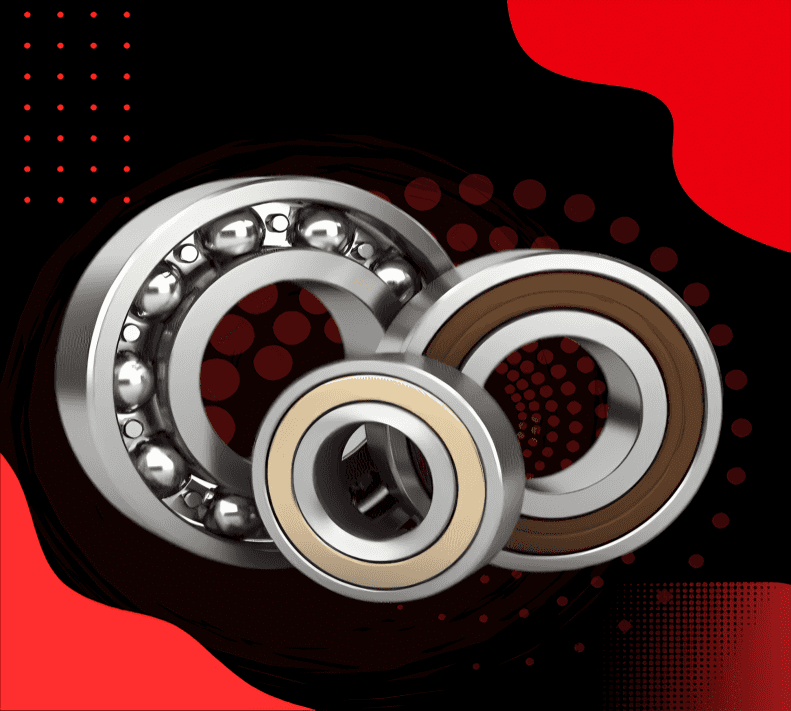

Bearings are used to reduce friction between two moving parts, allowing them to move smoothly and efficiently. They are commonly found in machinery, vehicles, and various mechanical systems where rotational or linear movement is involved.

There are several types of bearings, including ball bearings, roller bearings, plain bearings (also known as sleeve bearings or bushings), and fluid bearings. Each type has its own specific design and application, suited for different load capacities, speeds, and environmental conditions.

Bearings work by providing a low-friction interface between two surfaces in relative motion. For example, in ball bearings, small metal balls are placed between two rings (inner and outer raceways), and as one ring rotates relative to the other, the balls roll smoothly, reducing friction and enabling the rotation.

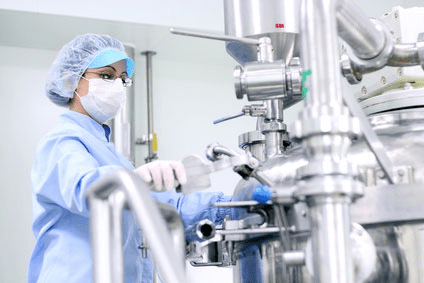

Selecting the right bearing involves considering factors such as load capacity, speed, operating temperature, lubrication requirements, and environmental conditions. It's important to consult bearing manufacturers or engineering resources to ensure that the chosen bearing meets the specific needs of your application.

Proper maintenance is essential for maximizing the lifespan and performance of bearings. This includes regular lubrication with the appropriate type and amount of lubricant, monitoring for signs of wear or damage, ensuring proper alignment and installation, and following any manufacturer-recommended maintenance schedules or guidelines. Regular inspections and prompt replacement of worn or damaged bearings are also crucial for preventing costly downtime and equipment failure.

We excel through innovation, resilience, and collaboration, setting higher standards and achieving remarkable outcomes