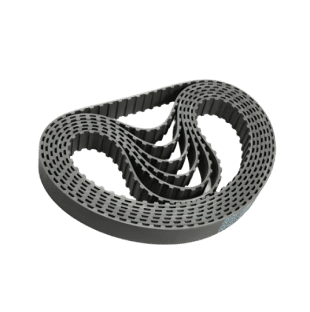

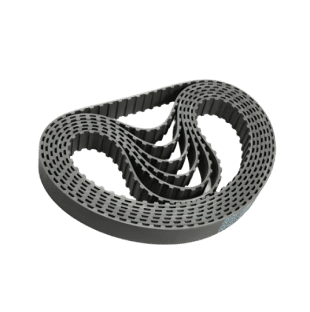

Timing Belts

- Timing belts are essential components in many mechanical systems, particularly those involving the synchronized rotation of shafts and pulleys. Comprising a flexible, toothed belt made from materials like rubber or polyurethane, timing belts ensure precise timing and power transmission between rotating components. These belts feature teeth that mesh with corresponding grooves in pulleys, allowing for accurate movement without slippage. Commonly used in automotive engines, industrial machinery, and robotics, timing belts offer several advantages, including quiet operation, low maintenance requirements, and high efficiency. However, they require periodic inspection and replacement to prevent failure, as worn or damaged belts can lead to catastrophic engine or machinery damage.

- The design and construction of timing belts vary based on specific application requirements, with factors such as belt width, tooth profile, and material composition influencing performance. Advanced timing belt systems may incorporate tensioners, idlers, and other accessories to maintain optimal belt tension and ensure reliable operation over extended periods. Additionally, specialized variants like synchronous timing belts feature precise tooth pitch and reinforcement for demanding applications where accuracy and durability are paramount. With proper maintenance and adherence to recommended replacement intervals, timing belts play a vital role in the smooth and efficient operation of various mechanical systems, contributing to overall productivity and performance.