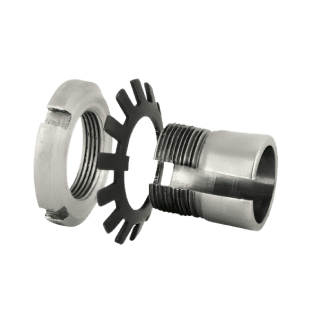

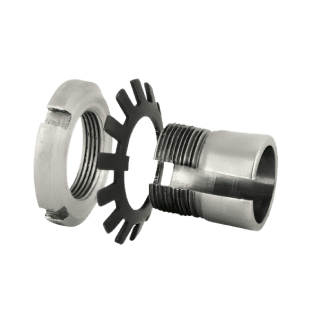

Bearing sleeve

- A bearing sleeve, often referred to simply as a sleeve bearing, is a cylindrical component used to provide support and reduce friction between rotating shafts and stationary parts in various mechanical systems. These bearings are designed to fit around the shaft, acting as a sliding surface to facilitate smooth rotation. Typically made from materials such as bronze, brass, or composite materials like PTFE (polytetrafluoroethylene), bearing sleeves offer excellent durability and resistance to wear. They are commonly found in applications where low-speed, low-load operation is required, such as in electric motors, pumps, and automotive components. The design simplicity and cost-effectiveness of bearing sleeves make them a popular choice for many industrial and commercial applications.

- Bearing sleeves play a crucial role in supporting rotating shafts while allowing them to move freely with minimal friction. These components are often used in situations where traditional rolling element bearings may not be suitable due to factors such as space constraints, environmental conditions, or cost considerations. Bearing sleeves are available in various configurations, including flanged, split, and solid designs, to accommodate different shaft sizes and mounting requirements. Additionally, they can be lubricated with oils or greases to further reduce friction and ensure smooth operation over extended periods. Despite their relatively simple design, bearing sleeves are integral components in many machinery and equipment, contributing to the overall efficiency and reliability of mechanical systems.