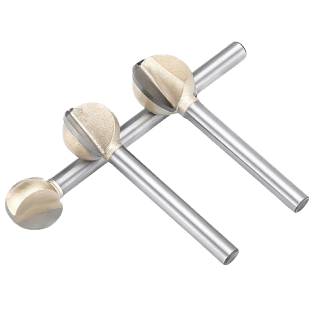

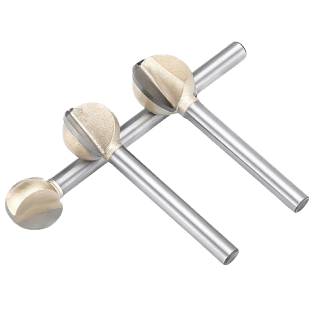

Ball cutter

- A ball cutter, also known as a ball end mill, is a type of milling cutter used in machining operations to create contoured surfaces or cavities with rounded profiles. Unlike traditional flat end mills, which have a flat cutting edge, ball cutters feature a rounded cutting edge shaped like a sphere or hemisphere. This design allows them to effectively remove material along curved paths, producing smooth and precise surfaces. Ball cutters are commonly used in 3D machining applications, such as sculpting, engraving, and mold making, where intricate shapes and complex geometries are required. They are particularly useful for generating fillets, chamfers, and other curved features on workpieces. Ball cutters come in various sizes and materials, including high-speed steel (HSS), carbide, and cobalt, to suit different machining requirements and materials.

- In machining operations, ball cutters offer several advantages over traditional flat end mills. Their rounded cutting edge reduces the likelihood of chatter or vibration during cutting, resulting in smoother surface finishes and improved accuracy. Additionally, ball cutters can reach into tight spaces and corners that may be inaccessible to flat end mills, allowing for more versatile machining capabilities. With proper toolpath programming and machining parameters, ball cutters can achieve precise surface contours and intricate details on a wide range of materials, including metals, plastics, and composites. However, it's essential to consider factors such as tool diameter, cutting speed, and feed rate when using ball cutters to ensure optimal performance and tool longevity. Overall, ball cutters are indispensable tools in modern machining operations, enabling machinists to create complex shapes and achieve high-quality surface finishes with efficiency and precision.